Installing conveyor systems and supporting structures for other machinery or utilities can soon eat into the floor area of a handling system and make it difficult to navigate. Hanging systems fixed to the underside of mezzanine floors are a versatile solution but usually come at the cost of future flexibility.

However, MiTek Mezzanine Systems has developed a simple and effective solution to this problem in the form of its MezzHead® brackets, which are designed to fix directly to the underside of its Mezzanine7® floor. "Our MezzHead brackets solution enables material handling equipment to be suspended in the space under the mezzanine floor," says Andy Parsons, Project Manager for MiTek Mezzanine Systems Ltd, "without forfeiting the flexibility to change the layout later."

Normally, conveyor systems are fixed to floor-mounted supports that, when bolted to a mezzanine, require drilling in the floor. With any such systems suspended from a Mezzanine7 floor via the MezzHead system instead, the facility is future-proofed as the brackets are simple to relocate, without compromising the strength of the mezzanine. In addition to being more space-efficient, the solution is less expensive due to fewer materials being required.

MezzHead accommodates last-minute layout changes

The flexibility afforded by MezzHead brackets in conjunction with Mezzanine7 also means that you can decide on the precise positioning for your suspended handling equipment later in the design phase of your project. Using a uniform load calculation to cover the equipment to be suspended, you can decide at the last minute where you want to position it, saving the time often lost in redesigning the system and thereby accelerating project handover.

Choice of 3 brackets

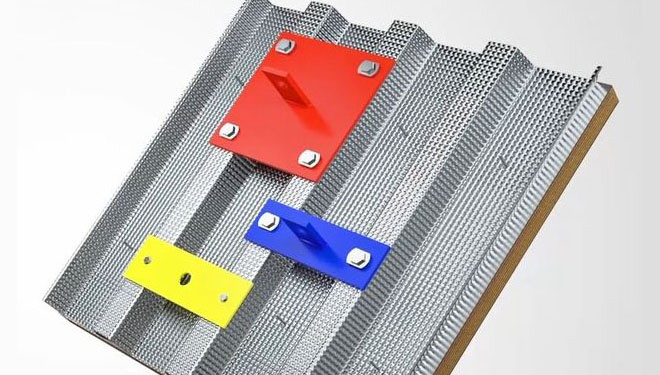

The unique MezzHead brackets are designed specifically for use with the company's patented Mezzanine7 floor system, which is up to seven times stronger than a standard mezzanine installation due to a special cold rolled pre-forming process applied to the steel used. The brackets are available in heavy duty (HD), medium duty (MD) and light duty (LD) versions, with different thicknesses of base plate as well as varying numbers and types of fixings to give maximum load capacities for the hanging systems of 1050kg, 375kg and 75kg respectively. “The corrugated profile of our bdeck40® decking support system allows the MezzHead brackets to be bolted directly to the bottom of the floor," explains Andy Parsons.

Automation drives demand for stronger mezzanines

The strength of mezzanine floors is becoming increasingly important as more companies are installing automated systems that are inherently heavy. "We are seeing increasing numbers of customers invest in automated handing equipment and robotic systems," says Andy Parsons, "and these require a stronger floor. This is why there is currently a high level of interest in our Mezzanine7 and MezzHead solutions. Together, they offer the ultimate turnkey solution for strength, ease of installation and flexibility for the future."

The Mezzanine7 solution accommodates point loads of over 2 tonnes, compared to around 600kg for a traditional mezzanine floor. As well as additional strength, the Mezzanine7 system offers the benefits of 75% less deflection (another important factor for sensitive automated equipment), a Class 0 fire rating and increased light reflectivity (for enhanced lighting efficiency and thereby cost savings). "What's more," adds Andy Parsons, "Mezzanine7 comes with a 10-year warranty for complete peace of mind."