Our connections and bracing methods add strength and integrity to the entire steel structure. There are various different option to provide lateral stability. What connections and bracing are use depends on your mezzanine requirements. Our design and engineering experts will always ensure the optimal methods are used for your project.

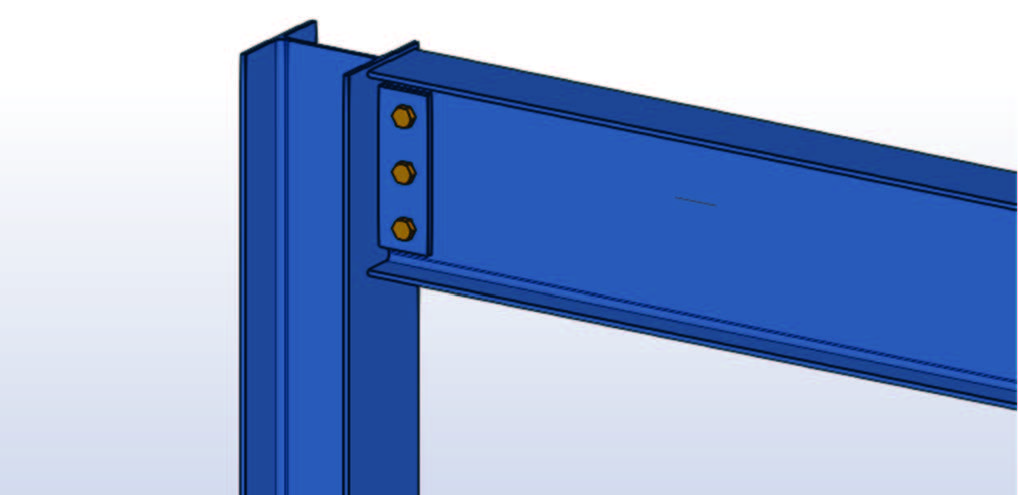

A semi rigid connection that is used mostly in moment frames to provide stability to a structure in a direction where bracing is not possible beneath the floor. The moment frames are usually applied across the whole floor in a direction to provide the necessary stiffness. It is also used on short cantilevers where the floor has to extend beyond the column foot print. These connections will with few exceptions be to a column flange.

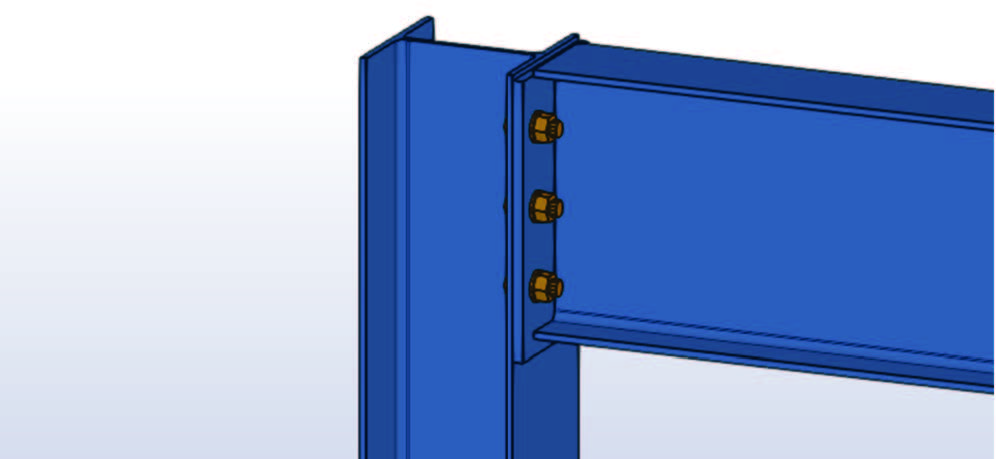

A flexible connection that has a lower capacity than flexi endplate but provides more flexibility when installing members in tight spaces making bolts more accessible. Works best on light weight structures to reduce cost and is most practical connecting beam to beam or beam to column flange. Keeps the fabrication on the column or main beam.

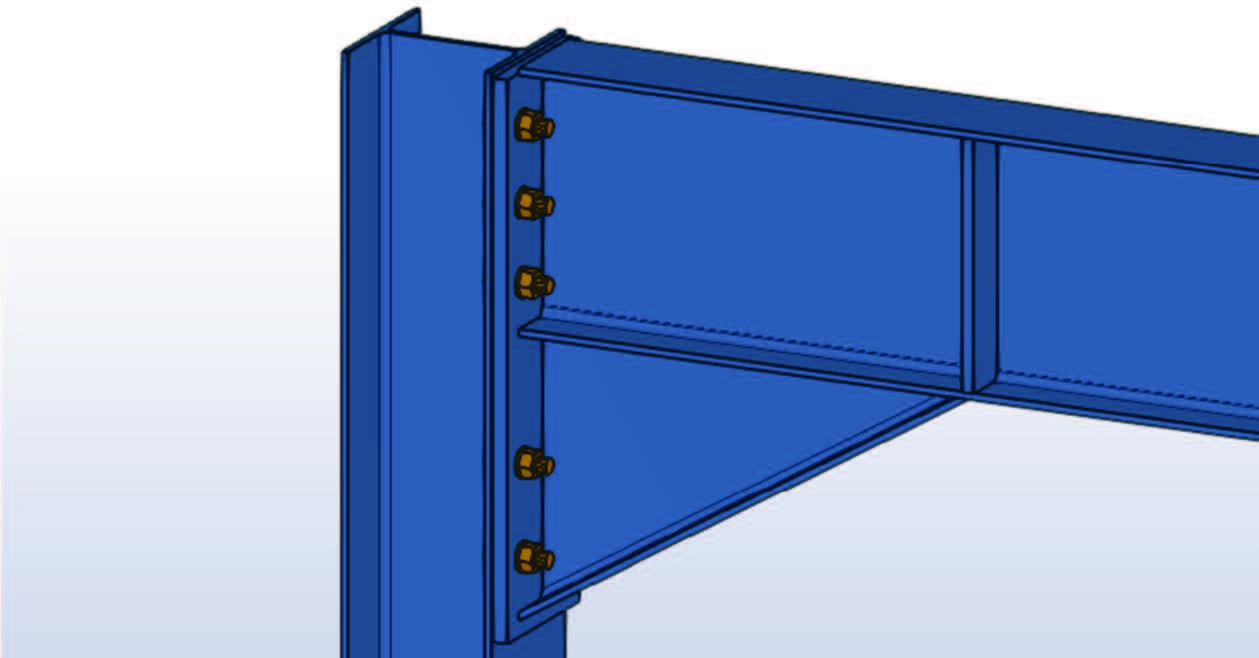

A rigid connection that is used in moment frames to provide stability to a structure in a direction where a greater amount of stiffness is required due to limited space for more moment frames or high horizontal loads due to equipment. These connections will preferably be only onto a column flange.

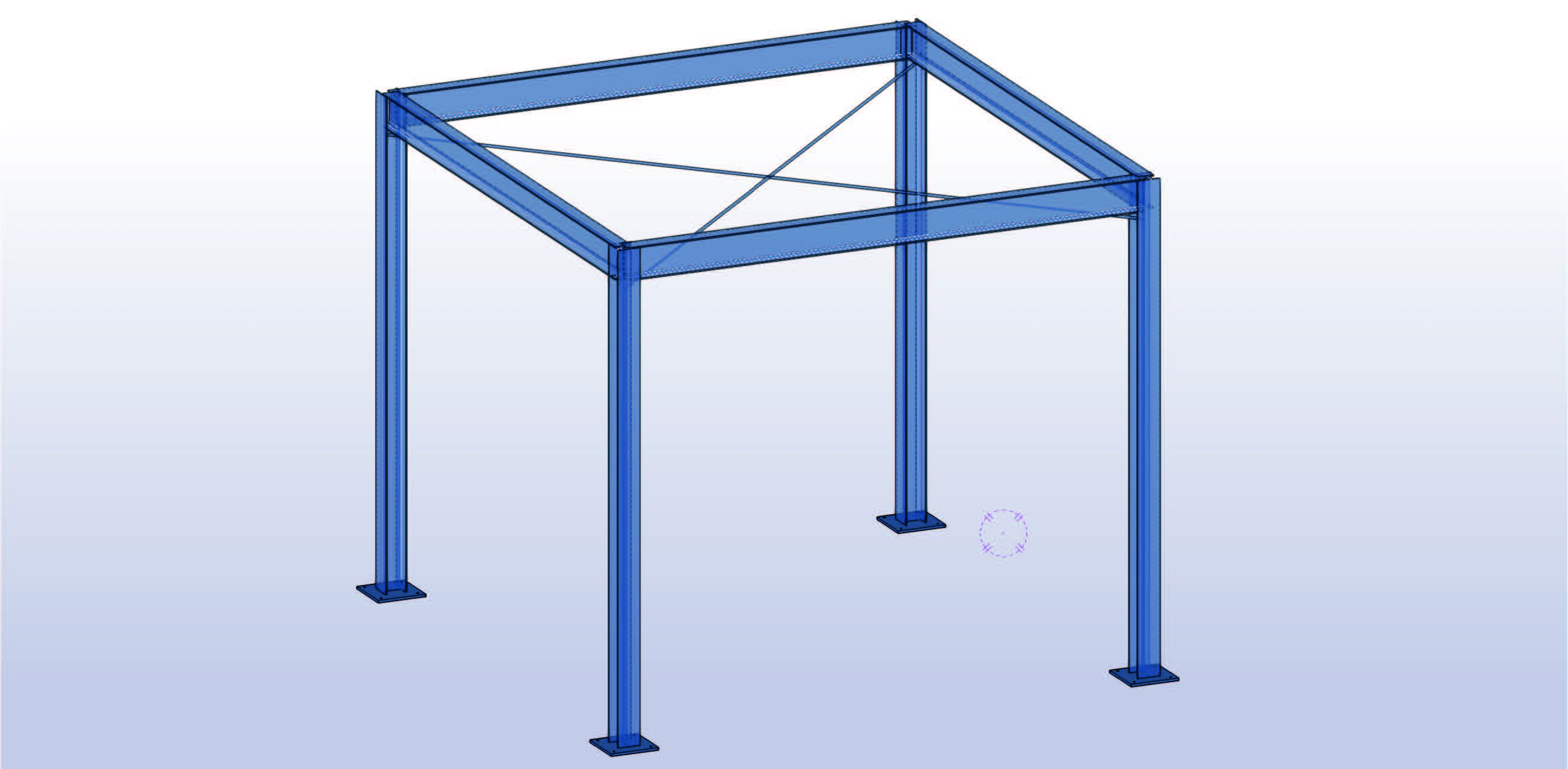

Often bracing will only be possible near the perimeter of a floor and if the floor has for example Mesh grating as a deck surface it cannot act as a diaphragm to support the inner column lines. Plan bracing will therefore be required to support the unbraced column lines back to a braced bay. Depending on cost and size of floor, plan bracing can take the form of cable or steel section like angle.

Request a quote

SendClose