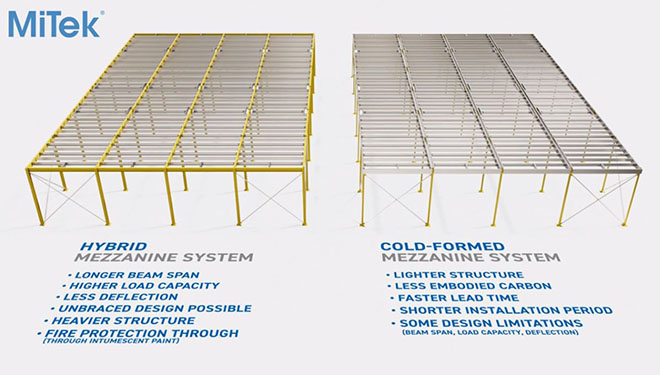

While the UK has traditionally used hybrid mezzanines, built using hot-rolled primary beams and cold-formed joists, the cold-formed design has been common for mezzanine floors in Europe. It can offer a number of advantages for customers, depending on the intended use.

“Purely cold-formed mezzanines can save costs when the application allows,” explains Geoff Green, Sales Director, “as they need less material and enable faster lead times. In addition, they improve carbon footprint due to their reduced weight. However, where large beam spans or high load capacities are required, a hybrid solution will still be the preferred option.”

The new cold-formed product was first showcased alongside our hybrid solution at the recent LogiMAT exhibition in Stuttgart, where it was very well received. The key benefits of the cold-formed mezzanine are its lighter structure, lower embodied carbon, faster lead time and shorter installation period. “There are some design limitations compared to the hybrid system, however,” says Geoff Green, “so we will always select the optimum solution to meet the needs of the customer’s application.”

The advantages of MiTek’s hybrid mezzanine solution include a longer maximum beam span, higher load capacity and less deflection. Although it forms a heavier structure, it is possible that bracing is not required and, in addition, fire protection can be ensured through the use of intumescent paint to the steelwork.

Our expert team is on hand to give you advice on whether a hybrid or cold-formed mezzanine design is the most suitable for your specific requirements.

Watch our video: