This article was created and published by Evolve Consulting Engineers:

https://www.evolveuk.biz/insights/mitek-mezzanines-a-carbon-reduction-collaboration

A carbon reduction collaboration

Evolve has been working with MiTek to develop an understanding of the embodied carbon in their existing mezzanines. This study will ultimately enable MiTek to start offering their clients more sustainable, reduced carbon options in the very near future. As the UK’s largest mezzanine subcontractor, MiTek is responsible for the installation of over 1 million square metres of mezzanines per year.

Mezzanines are typically formed from a hot rolled steel frame, with cold formed steel purlins supporting an engineered timber deck. While they are approximately five times more carbon efficient than buildings as they don't need their own foundations or cladding, etc., there is still potential for significant carbon savings. To put it into context, the embodied carbon associated with MiTek's annual mezzanine construction is estimated to be approximately 95,000 T CO2e per year.

In order for MiTek to present the potential benefits to clients in a clear, concise manner, we have built a bespoke carbon calculator tool for them to use and eventually embed into their estimating software, so that every tender is accompanied by an embodied carbon value.

To reduce the embodied carbon in MiTek’s mezzanine designs, we looked at three key criteria. The first is to analyse and optimise the client brief. This means ensuring that columns are spaced as close together as possible, within reason, to ensure that steel tonnage is minimised. Load criteria have been questioned, and the carbon savings associated with reducing design loads have been quantified, to help explain the impact of these changes to clients.

The second is to challenge MiTek's current material supply chain to replace them with more sustainable options, starting with MiTek’s current providers and then exploring alternative products that could potentially be added to the supply chain. This could include replacing Basic Oxygen Furnace steel with Electric Arc Furnace steelwork, for example.

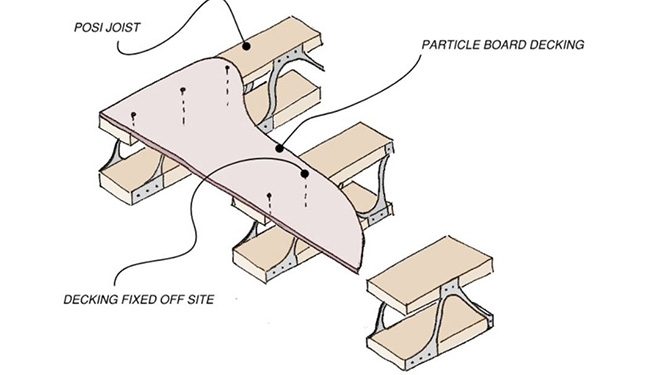

The third point is to challenge the design of MiTek’s mezzanines and swap the steel elements for more sustainable materials, with the goal of developing a greener mezzanine product that could be offered to clients. Various scheme designs have been considered, including mass timber, hybrid steel and timber, and hybrid steel and posi-joists. The company is currently developing its preferred option in order to ascertain viability in the marketplace.

Evolve is currently working on a white paper document with MiTek to explain the carbon impact of their products and the various options available to reduce it, which will be published later this year.